Spouting Cylinder

Spouting Cylinder Specification

- Frequency

- 50 Hz

- Automation Grade

- Semi-Automatic

- Power Source

- Manual or pneumatic operated

- Model No

- SC-20/40/60/80 series (as per size)

- Voltage

- Not applicable (manual/pneumatic)

- Accuracy

- 2%

- Capacity

- Varies as per model (commonly 20L to 80L)

- Temperature Range

- Up to 100C

- Feature

- Corrosion resistant, leak-proof design, easy-to-clean

- Core Components

- Cylinder body, spout, end caps, mounting brackets

- Measurement Range

- 20L to 80L (as per model)

- Equipment Materials

- Stainless Steel (grade SS304/SS316)

- Type

- Industrial Spouting Cylinder

- Usage

- Used for spouting, separating or filling applications in processing industries

- Display Type

- Analog scale gauge

- Dimension (L*W*H)

- Depends on capacity; typically 750 mm x 300 mm x 250 mm

- Weight

- Approx. 10-25 kg

- Inlet/Outlet Size

- 1" to 2" BSP/NPT thread

- Mounting Type

- Table-top or frame mounted

- Surface Finish

- Mirror polished

- Maximum Working Pressure

- 5 bar

- Cleaning Method

- CIP/SIP compatible

- Operating Method

- Hand wheel or pneumatic actuator driven

- Shape

- Cylindrical with conical ends

- Application

- Food processing, pharmaceuticals, chemicals, dairy

- Sealing Type

- Food-grade silicone or EPDM gasket

About Spouting Cylinder

Meritorious Usage, Applications & Features of Spouting Cylinder

Suited for spouting, separating, and filling in food processing, pharmaceuticals, chemicals, and dairy sectors, this spouting cylinder offers commendable reliability. It accommodates cylindrical materials with conical ends and supports both table-top and frame-mounted setups. Features such as a corrosion-resistant body, leak-proof silicone or EPDM gasket, easy-to-clean design, and manual or pneumatic actuation set it apart. The analog scale gauge ensures accurate measurement, making it a classic addition to any industrial processing line.

Certifications, Delivery Completion & Dispatch Assurance

All spouting cylinders are supplied with necessary certifications reflecting quality and compliance for international use. Distinguished by prompt order completion, our team ensures rapid dispatching from our primary FOB ports across India. Expect reliable delivery schedulestypically within standard industry lead timesensuring your operations remain uninterrupted. Our streamlined fulfillment process guarantees each order reaches you securely, with comprehensive documentation for exporter, manufacturer, and supplier requirements. Trust our track record for seamless order handling and on-time shipment.

FAQs of Spouting Cylinder:

Q: How do I select the appropriate model of spouting cylinder for my industry?

A: Selection depends on your required capacity (20L to 80L), desired mounting type, operation method (manual or pneumatic), and application area (food, pharmaceutical, chemical, or dairy processing). We recommend consulting our technical team for guidance based on your specific requirements.Q: What cleaning process is recommended for maintaining this spouting cylinder?

A: This equipment is CIP/SIP compatible, allowing you to perform automated or manual cleaning in place for optimal hygiene. Routine cleaning using approved agents and protocols will ensure longevity and compliance with industry standards.Q: When can I expect delivery after placing my order for a spouting cylinder?

A: Typically, order completion and dispatching occur within standard lead times, depending on capacity and customization. Our logistics team provides estimated timelines and tracking details once your order is processed and shipped from the designated FOB port.Q: What are the unique benefits of using this spouting cylinder in processing industries?

A: It offers a leak-proof, corrosion-resistant design for safe operations, easy-to-clean features, and food-grade gaskets. The robust stainless steel construction ensures durability, and the analog gauge enhances accuracy during spouting, separating, or filling tasks.Q: Where is the product primarily manufactured and exported from?

A: Our spouting cylinders are manufactured in India, at state-of-the-art facilities, and exported globally. We ship from major Indian FOB ports ensuring timely and reliable delivery to your location.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Physics Category

Steam Engine

Feature : Compact Durable Demonstrates steam power principles

Core Components : Cylinder Piston Flywheel Boiler

Type : Miniature/Model Steam Engine

Usage : Educational Demonstration Hobbyist

Equipment Materials : Brass Steel Aluminum

Automation Grade : Manual

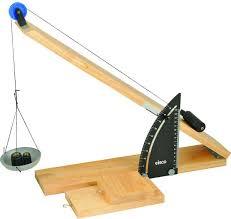

Inclined Plain

Feature : Inclined apparatus with calibrated measurements

Core Components : Wood Metal

Type : Inclined Plane

Usage : Physics demonstration Force calculation experiments

Equipment Materials : Wood and Metal

Automation Grade : Manual

Gold Leaf Electsroscope

Feature : Sensitive detection of electric charge

Core Components : Metal plates glass enclosure gold leaf electrode

Type : Electroscope

Usage : Used for detecting and measuring electric charge

Equipment Materials : Glass metal gold leaf

Automation Grade : Manual

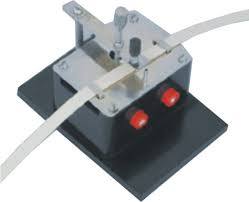

Tape timer

Feature : Tape cutting mechanism

Core Components : Steel Plastic

Type : Tape Timer

Usage : Industrial tape cutting

Equipment Materials : Steel Plastic

Automation Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free